Part 7: Handling and Shooting Impressions

© 2000 by John L. Marshall

First, let me say that since we are talking about compact .45s whose primary purpose is up-close self-defense, I will not address accuracy or ballistics. Each of these pistols is sufficiently accurate to place all shots into a 5-inch circle at 25 yards from a machine rest. Each will provide sufficient power with the right loads to effectively stop an assailant from doing you harm. In my hands, fired rapidly with the “Mozambique drill” technique of two shots to center mass, plus one to the head area of a silhouette target at seven yards, there was some difference among the pistols, but not a lot. I got the best accuracy in rapid fire with the Springfield, followed, in order, by the Glock, the H&K and the S&W. Since the Springfield is the only compensated pistol of the four and I have years of experience with 1911-style pistols, it is no surprise that I did better with it.

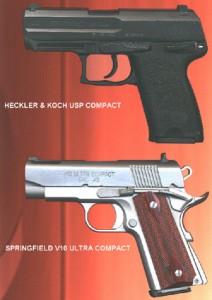

The Springfield V10, particularly since it was partially customized with a carry-bevel job, slimmer grips and a shorter trigger, handled and shot like a dream. It’s no secret that I like 1911 pistols. I have years of experience in handling and shooting them, so it was like shaking hands with an old friend when I fired this one. The pistol comes from the factory with a lot of sharp edges – the nose of the frame and the slide being particularly bad in this regard. Likewise, the slide stop needed some rounding and beveling. This was done on this particular pistol, and the custom work made it smoother handling and easier on drawing and reholstering. Rapid repeat shots with the V10 were a snap, and the compensator vents made it feel even better than a full-size pistol in recoil. The 1911 design and the high-ride beavertail grip safety keep the axis of the bore at about an inch from the top of your hand. This further eases the muzzle up-flip. The high-mounted conventional sights were excellent and provided a quick and sharp sight picture. I will tell you that the muzzle flash from the ports was spectacular in low light, particularly with +P loads and lighter bullets. For this reason, and because night sights will quickly become carboned up from the ports, this is more of a “daylight” gun than an “evening” gun. The pistol ran through its paces with no problems at all. There were zero malfunctions in extended firing. For a fast first shot from “cocked and locked” mode out of the holster, and for fast and accurate repeat shots, this little pistol really shines. The trigger pull was match grade, crisp with no creep, letting off at just under 4 pounds. The aluminum frame makes for light weight, and it’s among the best of the compact 1911 designs for lightness. Of all four pistols, I’d rate the Springfield second in concealability to the Smith & Wesson. Although the maximum width of its grip is the same as the Glock (the worst for concealability), its shape is more ovoid in cross section, and the edges are thinner. Thus, it doesn’t “print” as noticeably as the Glock when carried in a strong-side belt holster under clothing.

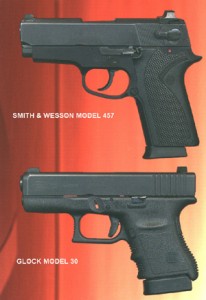

The Glock 30 is one helluva little pistol. Its big advantage is in firepower, and it’s the only one of the four to pack the legal maximum 10-round magazine into a compact configuration. Having the big full-size Glock 21 without pre-ban magazines of 13-round capacity seems almost pointless if this pistol is available. By the way, pre-ban high-capacity magazines will fit and function fine in the Glock 30, so back up magazines can be of up to 15-round capacity (with a +2 extension). Of the four pistols tested, the Glock was the most accurate in deliberate fire, and the second most accurate in rapid fire. The design of the pistol, since it doesn’t need room for a pivoting hammer, allows for a very low bore axis. The center of the bore is only .70” from the top of your hand when firing. This means that it recoils in more of a straight line, and the muzzle flip is minimized. The Glock “safe action” trigger takes some getting used to, but if you think of the trigger pull on a Garand or M14, you can visualize it. It’s two-stage, with a light take-up and about a 5.5 lb. let-off. Once you get used to it, it’s workable. Also taking some getting used to is the fact that the pistol has no manually-operated safety. It can be carried safely fully loaded with no danger of discharge in a holster that completely covers the trigger. The only way the gun can fire is with a deliberate pull on the trigger, depressing the built-in safety mounted directly on the trigger. This is characterized by some as “leaving the key to the henhouse with the fox,” but there is no denying the popularity of the concept. The flexibility of the polymer frame, the low bore axis, the two-stage recoil spring arrangement and the width of the grip all combine to minimize apparent recoil. The factory plastic sights should be dispensed with in favor of metal sights with tritium inserts at the first opportunity. This pistol, with the tritium sights, did well in low light. The grip angle of the Glock is more slanted than that of the 1911, so if you are used to a 1911, the gun will come up to your line of sight pointing high. This takes some momentary adjustment until you get used to it, and point shooting is not recommended until you do. The Glock functioned flawlessly through extensive firing with many types of ammo. Reliability is one of the hallmarks of this design. It can be very difficult to load the last couple of rounds into the magazine with your issued magazine-loading tool (your thumb). Glock provides a mag loader as part of its factory package, but it’s not something you’ll carry around a lot. The mags get easier to load with use, thank goodness. The standard slide release is tiny and hard to actuate with the thumb. This particular pistol was equipped with the factory-optional “extended” slide release, which has a little nubbin on it for easier manipulation. It’s better, but not by much. Glock recommends releasing the slide by pulling back on it, and that is the school combat solution, anyway. Technically, the Glock is a “double action only” pistol. However, there is no “repeat strike” capability with the Glock design, as a second pull on the trigger will not load and trip the striker again. You will have to execute the “tap-rack” drill to get it back into action after a bum round. The magazine drops free of its own accord when the mag release button is pressed. For concealed carry, the Glock’s clunky shape, unfortunately, is its undoing. It’s thick, squarish, and not the most ideal for holster carry under a shirt or other outer garment. The best concealment holster I’ve found for this pistol, incidentally, is Glock’s own economical “sporter” model, made of very thin plastic.

If you are used to the controls of a 1911 pistol, the H&K USP Compact should suit you just fine. The safety, slide release, and mag release controls are all where you would expect them to be, and your developed motor skills will apply well to this gun. Just remember to press down on the mag release instead of in. This is easy and natural. Even easier is pressing down on the right-side mag release with your right index finger. Suit yourself. On this pistol, you can apply the safety before you rack the slide to load a round, giving you an extra safety margin not available with 1911-type pistols. In the 1911 design, the hammer must be cocked before the safety can be applied. I mentioned earlier that the bobbed hammer can be cocked, and the safety design allows you to do this with less trepidation than with the S&W, for example. The procedure is to apply the safety, point the pistol in a safe direction, and pull the trigger gently. The hammer will lift and stop at about “1/2 cock” position, and you can then press it the rest of the way back with your thumb. You are now cocked and locked. I’d prefer a hammer with a thumb spur, but this one was designed for concealed carry and snagless draw. Needless to say, this procedure should not be performed under extreme stress lest the sequence above be reversed and a negligent discharge become the result. The pistol can be carried safely with the safety off and the hammer down, ready for a double-action first shot. This is the preferred means of concealed carry. For open holster carry, the hammer should be down and the safety applied to help in case an opponent snatches the gun from the holster. The moment of confusion that could result from the safety being on might work to your advantage should the gun be turned against you. This pistol fits my (average) hand very well, particularly with the finger-rest magazine. It still fits pretty well with the smaller-baseplate magazine, and that’s the one to insert for concealed carry. The H&K USP Compact runs a close third to the Springfield for concealability. The grip area, which is the hardest part of a pistol to conceal under clothing, is nicely shaped and second only to the S&W for thinness. The checkering and stippling molded into the polymer grip give a secure hold. The double-action trigger pull is nothing to write home about, coming in at a somewhat gritty 12 pounds. The single action pull is pretty nice, with about ¼ inch of slack, and then a creep-free let-off of about 4 1/2 pounds. If action were imminent, I’d prepare for it by going to the cocked-and-locked mode. A creepy double-action first shot will not make for accuracy. Recoil is quite manageable. The bore axis is about 1 inch higher than the hand and the muzzle flip is not severe. There were no malfunctions in extended firing. I found that a uniformly strong grip serves to give you better accuracy with this pistol, as it’s more sensitive to varying grip strength than the others. The tritium sights give a good, clear sight picture and work well in reduced light. The decocker available to you by pushing the safety lever all the way down should be used to go from cocked-and-locked to down-and-double action. A flip up on the lever then gives you an extra margin of safety in the double-action mode. The grip fits the hand nicely. This is a nicely-designed, very functional pistol that was obviously intended for the U.S. shooter used to operating a 1911. It gives you features not available on the 1911, but allows you to operate it quite similarly if you wish.

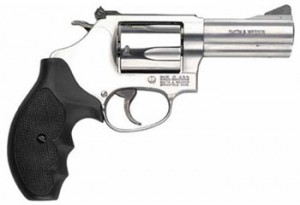

The Smith & Wesson 457 is a study in contrasts. It is easily the most concealable of the four pistols evaluated. The grip is slim and nicely shaped, and it almost disappears under clothing. At the same time, the gun suffers somewhat in the shooting department. The bore axis is about 1.1 inches above the top of the hand. Also, the curve of the grip places the pivot point of the hand somewhat lower than would be ideal. This results in more muzzle flip than with the other pistols. Accuracy, while acceptable, is not its strong suit. I personally dislike the slide-mounted safety-decocker, which does not allow a “cocked and locked” carry. I also am not a fan of pistols having a magazine safety. In my opinion, this is an attempt to make gadgetry substitute for training. To clear any pistol properly, the magazine should be removed first, followed by racking the slide to eject the round in the chamber. This should be written in stone and drilled into every semiauto user’s head. If you only remove the magazine on this gun, you have totally deactivated the pistol. It does make it safe, but it completely prevents you from firing the one remaining round you might have in the chamber. Without a magazine, this pistol is not even as effective as a rock. The magazine safety can be deactivated, but removal of any “safety feature” could get you in trouble if you use the pistol for self-defense and have to justify your actions in court. The double action pull is smooth at 11 pounds. The single-action pull is crisp at about 5 pounds, with about 1/3 of an inch of slack. If your index finger is fleshy, the trigger has the annoying habit of pinching it at let-off unless you use just the tip of your finger to press it. Thumb-cocking the pistol would require squeezing the trigger slightly to lift the hammer to the point where your thumb can get in front of it to pull it all the way back. This is definitely not recommended due the danger of a negligent discharge if you pull the trigger too far. The H&K will allow this procedure, but it has a safety that stops the trigger from pulling all the way through when applied. The S&W is completely reliable, with no malfunctions occurring in extended firing. The matte blue finish on the slide and the black anodizing on the frame are not especially durable as finishes go, and holster wear will take its toll rather quickly. The rock-hard durable finishes on the H&K and Glock pistols, or the stainless-bare aluminum finish of the Springfield are superior. The tritium sights on this pistol, provided by Trijicon™, give a good sight picture, day or night, and the pistol shot close to the point of aim. The dovetailed factory plastic sights are cheesy in my view, and almost demand replacement.

Previous: Frames | Next: Disassembly and Maintenance