By R. Fuzzy Fletcher

I have been a revolver shooter for many years, and I always had doubts on the reliability of one of those new fangled auto pistols. Their metallurgy was questionable for a few years, and the reliability was also a big question in my head.

With a revolver you could get 6 you could count on.

Then along came technology, new metals and research into galling of like metals and ways to prevent it. As a toolmaker, I have spent the last 27 years in machine shops, so I have a fairly good idea of the properties of metals and other machinable materials.

I trained hard with my wheel gun. I actually carried two, a S&W model 10 in .38 special and a snubby of Charter Arms manufacture, or more recently, a model 85 airweight from Taurus. I became an NRA pistol and personal protection instructor. I attended many classes at the Firearms Academy of Seattle (FAS), not just for Firearms but for knife-counter knife and OC spray and any other topic I could take from them. I had the privilege of helping teach and safety for a few classes before I stepped up and took a class from a nationally recognized trainer, Massad Ayoob. What a great class, and being offered at my favorite training center made it easy to take. After the 2nd class with Mas, and the 3rd class that I worked the line for, he asked me to teach the Revolver portion of the reloading section of his class, an honor indeed. My belief in “Stress-Fire” was alive and well.

At FAS, I was introduced to an instructor that was to become a life long friend and mentor, Mr. Jim Cirillo, NYPD, Stake-Out Unit, retired. He left NYPD and went on to work for U.S. Customs and designed their Firearms training facility and updated their firearms program.

I have taken many of Jim’s classes and spent many an hour listening and learning from a man that has been there, seen the “Elephant” and gone home to his family. This isn’t theory or arm chair BS; this is Life on the street.

He used a wheel gun, and every chance I had to train with him in a class or privately, we worked on my skills with a round gun. With a lot of practice and help from Jim, I finally fired a perfect qualifier and went on to finish 3rd in the state in a stock gun championship. Finally technology caught up with him. After researching many weapons Jim moved on to a Glock, he found it worked for him. Me? I didn’t take to the Glock too well. I bought three and sold three, in 3 years. Each time it was a new size and/or caliber that I had hoped would take me there.

Technology was to the point where I felt I could put my life on the line and that of my family. I insisted on 100% reliability and a good set of sights. I had this with a revolver but as age caught up with me so did my waistline and the daily packing of a couple of wheel guns was getting a bit too much for the pants. I dug my old 1911 style Government Model out of the case and dusted it off. It felt good in the hand as only the 1911 can feel. It was flat and held more rounds then my round gun, and with the right magazine it held as much as both my wheel guns together. (I still carry a back-up; it just got moved).

I was comfortable with it. I researched ammo designs and felt that .230 gr. Hardball was the way to go. I bought a bunch, to be reloaded later, and down to the range I went. I put about 300 of the factory rounds thru it and had no malfunctions, so I felt it would be reliable on the street.

Now the only thing left was to scratch an itch that most folks with .45 hardball don’t get – I wanted a round that would match the stats of the street proven .357 magnum. OK now, relax. All you folks that are ready to write me a letter to explain what an idiot I am because .45 hardball has been working for 90+ years and what the heck is my problem, please remember I’m a toolmaker, and toolmakers are tinkers by nature. Besides, the weapon was a Norinco, and if I ruined the barrel in my trials I could put a “Bar-Sto” in it and it would shoot better anyway.

Why did I pick a Norinco? Well, I had read that Bill Wilson would work on Colt’s, Springfield’s and Norinco’s and I could get one for about $200, so I went for it.

After much research and a little luck, I arrived at my caliber (See Historical Notes) and pistol of choice – a 1911 style pistol shooting a necked down .45 ACP case with a wadcutter .357 Golden Saber bullet. Why the Golden Saber? Because the FBI has had good luck with it, as have some of the police entities around where I live.

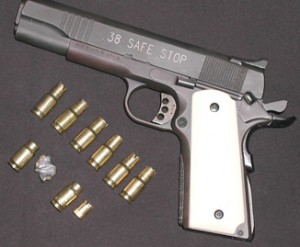

The ballistics are 1450 FPS out of my 5” barrel. I also use a 20 lb. main spring and a shock-buff. The advantages of this caliber and bullet style are that a flat nosed bullet has less of a chance of ricocheting off of another round object. It will penetrate car body metal at a greater oblique angle, and it opens up in to a rectangle due to the split that I put in the bullet (see accompanying photo). I arrived at the powder charge I’m at now, by working with many powders and weights of powders to try and get to 1500 FPS, while keeping the pressure down to what I knew the 1911 could handle. I used the 125 grain .357 HP bullet because that was the round that posted the stats I was trying to copy. I arrived at 1450 FPS and felt that would achieve the results that I wanted. I’m now beginning to experiment with a 90 grain bullet to achieve 1700+ FPS, because it is my understanding that at that speed a bullet will continue on its original trajectory, no matter the shape of the surface it might hit.

Another advantage of using a 1911 launching pad is that all my Government Model holsters and mags work just fine. If I went with a 38 super or a 9×29, I would have to change slides and mags.

To arrive at the ability to shoot the .357 bullet out of a .45 ACP weapon, one must buy a .38 super barrel and have it re-worked to hold the necked down cartridge in the chamber. I did this by building a reamer that matched the profile of my finished round and carefully reaming out the new, 3.8 Super barrel.

I got to go pack now. Cirillo is flying out, to FAS, for another class this year and I get to go do some more training with a friend.

I’d like to thank Jim Cirillo, Massad Ayoob and Marty Hayes of FAS for all the years of help, training and understanding as I took this journey.

Historical notes on the .38/.45 Safestop

My search for the best personal protection ammunition for me began with finding the historical notes below. These notes are taken from the 6th edition of Cartridges of the World.

First we have the 38-45 Auto aka. 45-38 Auto Pistol and the 45-38 Clerke.

The 38-45 Auto was designed by Bo Clerke of the Armory gun shop, Burbank, CA and was first announced publicly in the October, 1963 issue of Guns and Ammo magazine in an article by Howard French. The 45-38 Auto is based on a .45 ACP case necked down to accept standard .357 bullets. Super 38 ACP barrels are reamed out to the new caliber and used in the 45 Colt Auto pistol without any other changes.

One of the inherent faults of most semi-auto pistols is their inability to digest cast or swaged lead bullets. Much time and effort has been devoted to correcting this, and the individual hand loader can effect considerable improvement. The necked down design of the 45-38 eliminates any and all feed and chambering problems with light or standard loads. With a straight case, such things as bullet shape, seating, depth, hardness of alloy, etc. are highly critical. With the necked case this can be ignored. The idea behind the 45-38 was to produce a satisfactory target round that would function with any type bullet and any load sufficient to operate the mechanism. However, it should also be an excellent field cartridge because it will allow the use of hunting type bullets. There is a definite need for an improved auto pistol hunting cartridge. Case configuration is the same as the 38-45 Hard Head but the loading data is not interchangeable.

The 38-45 Hard Head is nothing more than the 45-38 Auto in a different dress. The 45-38 Auto is based on the .45 ACP necked down to 38 caliber. The 38-45 hard Head is the same thing but instead of using the standard 45 ACP case with it’s 19,900 CUP pressure limit, this one uses the 45 Winchester Magnum or the 451 Detonics case both of which are rated at 38,00 CUP. It allows the use of hotter loads without the danger of case failure.

The idea originated with Dean Grennell, of Gun World magazine fame, who was working on improving the performance of the 1911 Colt auto pistol for some years. The 38-45 Hard Head was fully reported in the November, 1987 issue of Gun World magazine.

Velocities of 1500fps were achieved with a 124-grain bullet from the 5” barrel of a modified 1911 type pistol.

General Comments: Attempts to upgrade the ballistics of cartridges fired in the 1911 Model Colt auto are fraught with frustration because of two limiting factors: the weakness of the partially supported case and the strength of the action. If you push the cartridge too far, it will fail, and if you put too much strain on the action, severe damage can result. The answer is a stronger case and stiffer recoil springs, something that Dean Grennell has used successfully on a number of occasions and has done so again here to upgrade the 38-45 Auto and develop sort of a super .38 Super auto. The 38-45 Hard Head was also tested in a T/C Contender with a 10” barrel and developed velocities of over 1700 fps with the 124-grain bullet. Bullets used in testing were .355-.356 inch diameter (9mm).

After getting permission from Jim Cirillo to use his wadcutter style bullets for my personal use, I started to wonder what I could do to push the .357 diameter bullet to the speed necessary to produce similar stopping effects that can be found with the .357 Magnum revolver round. I could just keep using my wheel gun but I wanted something that was flatter and held a little more ammo. So I went back to carrying my 1911 style .45 auto.

I could not stop thinking about the possibilities of pushing the .357 bullet out of a flat 1911. I then started researching the possibilities. The .38 super was the first cartridge to come up, that would work but I heard a few things about the cartridge that I did not like and it looked like I would still have trouble feeding Cirillo’s wadcutter bullets. I then checked out the .357 SIG. Same issue – it was available in a 1911 pistol but it would not reliably feed the wadcutter bullet I wanted to use. Another issue for me was that I wanted a true .357 diameter bullet not a .356 diameter (9mm). I know this is one small thousandth of an inch. The point was I wanted to push an actual .357 revolver bullet not a 9 mm.

So I started to try necking down the .45 ACP case. I did not then know of the others work, mentioned above, at that time. After many failures, I put the project on the back burner while I concentrated on making and selling the Cirillo style bullet, now known as the ”Safestop” bullet.

Just recently I saw an article in one of the gun magazines about the new .38 Casull, I have respected Mr. Casull’s work for a long time and was interested to see what he had come up with now. What I found was what I’d been looking for. A beefed-up and necked-down case to fire 9mm ammo (.356 dia.) from a 1911 type pistol. Dick had designed a new case and beefed-up John Browning’s designed 1911, lengthened the barrel to 6” and he was flying.

I took my project off the back burner and was ready to try again. I contacted Casull and found out that brass was available thru him or Starline brass. The first lot manufactured uses large pistol primers, and it is my understanding that the next batch of brass will be using small rifle primers.

After I got my brass and ordered a set of RCBS dies (from Mr. Casull) for the new Casull round, I started to experiment.

Many tries later I finally got my round perfected. A .357 diameter 125 grain bullet out of a bottlenecked .45 case. These rounds are traveling a little less than 1500 fps. The other nice part is that I can still use all my .45 mags and holsters. The only thing I changed was my re-bored barrel. While Casull uses 9 mm bullets, I use the .357 Speer Gold Dot (125 grain) and the Hornady XTP (90 grain). I have no velocity info on this round yet as I have just started to work on it. As we speak, I’m using powder from Western Powders. They have worked very hard to help me in this project and offer a great assortment of powders for those who need it.

Realizing that Cirillo patented his bullet in the 60’s and Bo Clerke had his design published in 1963, you could say this is a rebirth of an old design.

There are other articles out about Cirillo’s wadcutter design that I find so effective and I’ll tell you more about that elsewhere.

Thus the 38-45 Safestop is Born.

Questions? E-Mail Fuzzy at [email protected]

Comments, suggestions, contributions? Let me know